avance embroidery machine thread breaks

If you suspect this is the problem contact the digitizer. SLOW YOUR EMBROIDERY MACHINES SPEED DOWN.

Avance 1504 Multihead Commercial Embroidery Machine Demonstration Youtube

An excessive amount of adhesive build-up on the needle can make them drag and break threads.

. Of NeedlesColors - 12. Insert the bobbin again and re-thread. Problem may re-occur without proper troubleshooting.

Ad We Have All Of Your Embroidery Needs Covered. Press TCUT to cut thread still attached to garment2. It is easier to make stitches on a flat surface.

The reason they do that is simple. A bobbin designed specifically for this machine is not. If this is occurring you need to take a look at the way you use your adhesive spray.

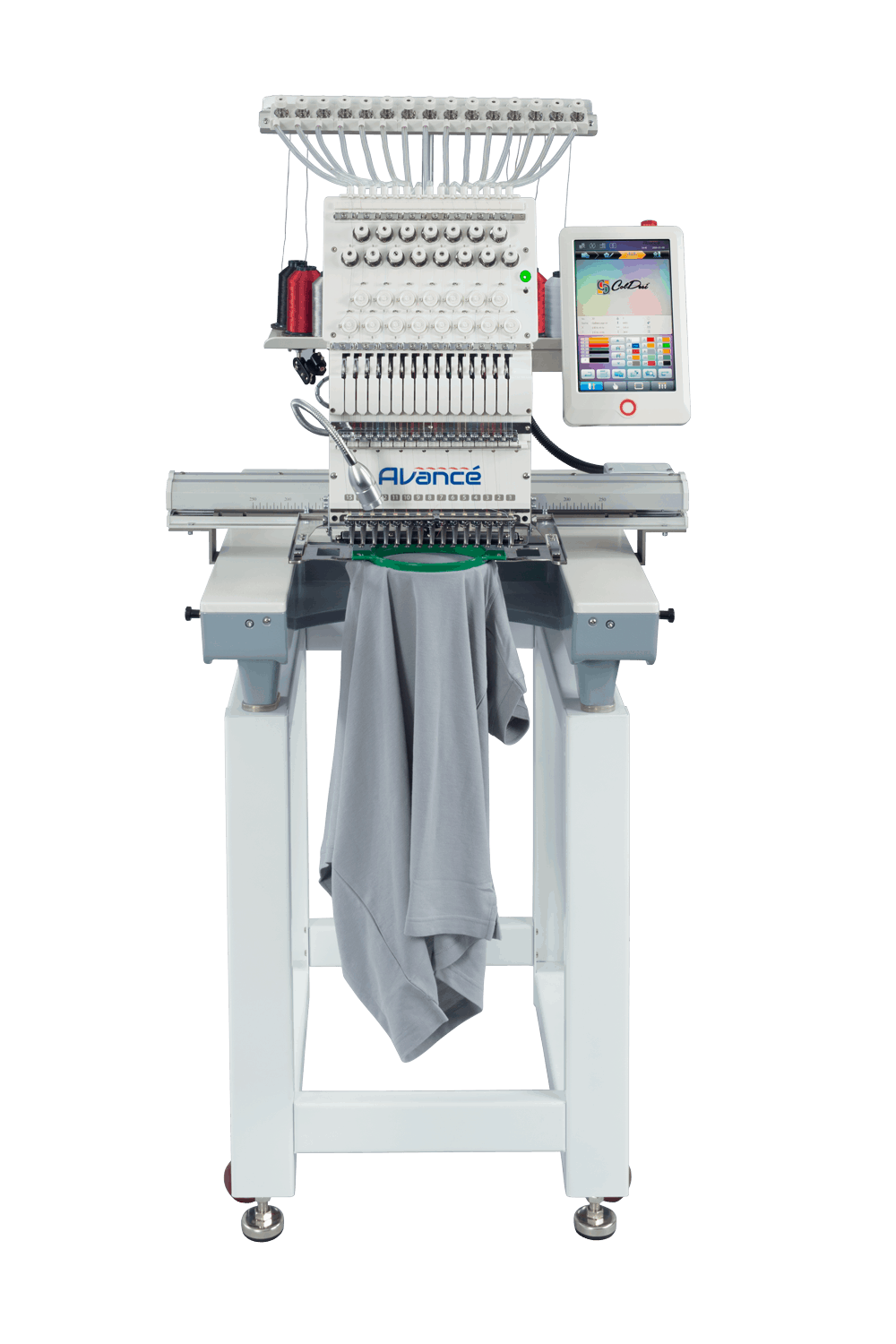

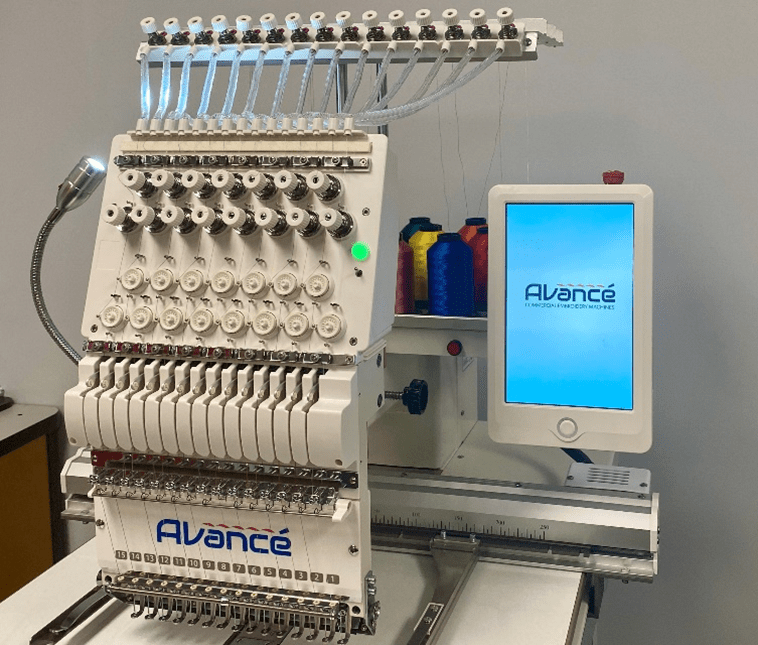

The thread quality is too weak due to age of thread. Use the Troubleshooter below. Thats what the Avance 1501C from ColDesi has to offer.

Well examine three areas where metallic thread can get snagged up. Long tails can cause the bobbin thread to tangle when the machine begins to stitch. Therefore you should place a lock stitch and resume the embroidery on a low speed in order to avoid thread coming out of needle at this moment.

Conversely on the flats the situation is different. Remove the loose thread. Full color touch screen control panel - makes it so simple to use.

Unbeatable Prices And Selection. 12 1000 meter cones of Royal Thread. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features Press Copyright Contact us Creators.

It is difficult to make stitches on caps. The digitizer might have left too many layers of stitching in one spot making it very dense causing the needles to break. Tie-offs protect the design from breaking loose.

1 - At the spool or cone 2 - Inside your machine. We Pass Savings On To You. If your Embroidery machine isnt timed appropriately it can cause many problems along with thread breaks.

Metallic thread will curl when unwound off the. Nowadays the digitizer wont have any trouble inserting a tie-off. The thread break sensor on Avance machines is automatically activated when a thread breaks.

Repair thread break by re-threading upper thread or replacing bobbin. Most of the time bobbin tension should be set at about 25 grams and the top thread should be at 110 to 150 grams for polyester 100 to 140 grams. This applies to Embroidery Machines with Check Spring sensors as opposed to ones with wheel sensors.

She can easily fix it. 28 on board fonts for easy monogramming and lettering projects. Heavy duty metal wheeled stand.

Trim the thread to 3-4 cm before inserting the bobbin and case into the hook assembly. 101 Full color high resolution touch screen interface. The thread break sensor on machines with check spring type sensors can sometime malfunction if the.

True commercial embroidery thread breaks have many causes including abrasion excessive tension or stress. Browse Our Huge Selection Of Top Brands Online. If none of the above helps and youre SURE that the thread isnt catching anywhere - try to lower top thread tension.

USB Port - Convenient design load. You can schedule training here. The thread keeps breaking and Im talking about every 40 to 50 stitches.

Simply say yes to more jobs and get them done faster with this truly industrial embroidery machine. If re-threading doesnt help - try to take a new bobbin. The faster your machine is running the more tension youre putting the thread under.

Remove any knots or tangles. The first step is checking the tightness of the bobbin thread. Caps are harder for needles to penetrate.

A HUGE embroidery field more and larger hoops 15 colors of thread on deck for any job and the commercial components it takes to run a machine all day every day. If you are experiencing False Threads Breaks on your embroidery machine it could be due to the connection at the thread break sensor. While stitching out a job you should have a thread break as soon as the job ends otherwise the job will continue stitching wasting time and material.

The embroidery design. If your needles are breaking repeatedly on the same design it may be a design flaw. Your machine manual will show you how.

Press START to continue sewing. Answer yes or no questions and. Press or press and hold STOP to move sewing position to just before the break.

Start off by making sure your machine is set up correctly this only takes a few minutes and youll be stitching with metallic thread happily for hours. HUGE design memory on board - 800 designs or 100 million stitches. Firmly set the fabric in the embroidery frame so that it is taut.

Id recommend between 300 400 stitches per minute for optimal results. FAST design load - saves production time. For example broken needles poor.

Avance embroidery machine review. So getting trained one problem at a time is a recipe for frustration not success. The theme on the needle increases the chances of it to break.

When the machine resumes the embroidery in only has a short thread end to make the loop. The reason behind this is that you have to stitch on a curved surface. Starter backings toppings and supplies.

The thread quality is poor. Heres a short video showing you how to create your own horizontal spool holder. Using a flat head screw that was provided to you labeled Minus Driver Small tighten the adjusting screw one to two minutes 1 to the right.

Operating an embroidery machine sewing out a design choosing the right supplies are all inter-related. Embroidery Area - 14 x 78 200x360mm Machine Size - 23 w x 23 d x 63 h includes metal stand Weight - 17637 with stand. The thread is loose in the hook area or the hook does not rotate smoothly.

If a thread breaks during the restitching process the Avante. Take the bobbin out. 3 - At the needle.

I am using Sulky thread to machine embroider designs. I have checked everything I know how to check ie new embroidery needle machine Viking 1 sets tensions automatically is threaded correctly bobbin wound with bobbin thread through finger eye on case fabric hooped correctly etc. Power - 110V60Hz and 200V50Hz self-adaptable worldwide.

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Avance 1501c Multi Head Embroidery Machine Options Avance Commercial Embroidery Machines

Bravo Embroidery Machine Thread Break Troubleshooting Youtube

Commercial Embroidery Thread Breaks True Or False

Coldesi Inc Announces The Release Of All New Avance Commercial Embroidery Machine News

Setting And Troubleshooting Tensions On The Avance 1501c Youtube

Tech Talk Stop Breaking Needles Avance Embroidery Machine Youtube

Why Thread Breaks Happen And How To Avoid Them Ricoma Blog

Monogramming Machine Google Search Computerized Embroidery Machine Swf Embroidery Machine Machine Embroidery

Avance Commercial Embroidery Machine Colman And Company

Melco Bravo Package B 16 Needle 14x12 Embroidery Machine Full Design Shop Commercial Embroidery Machine Machine Embroidery Machine Embroidery Patterns

Avance Single Head Embroidery Support

Avance Training Repairing A Thread Break Bobbin Run Out Youtube

Troubleshooting Embroidery Thread Breaks Youtube

Commercial Embroidery Machine By Avance Best Single Head Brand Usa

Avance 1201c Avance Commercial Embroidery Machines

Swf Embroidery Machine Training Tip Cap Driver Changing Needle Plate Youtube Swf Embroidery Machine Machine Embroidery Embroidery